The Ultimate Guide to Efficient Cnc Fixture Design for Manufacturing Success

By:Admin

Introduction:

In a breakthrough development within the manufacturing industry, an innovative CNC fixture design is set to transform production processes, providing greater efficiency, accuracy, and versatility. This cutting-edge technology marks a significant milestone in manufacturing, empowering companies to improve their productivity and competitiveness in the global market.

The Company's Vision:

Born out of a deep passion for revolutionizing the manufacturing domain, the company behind this groundbreaking CNC fixture design aims to redefine industry norms. Their team of experienced engineers and technicians have dedicated years of research and development to create this state-of-the-art technology, which promises to streamline operations and enhance overall production quality.

The CNC Fixture Design:

This remarkable CNC fixture design incorporates a myriad of advanced features that address the challenges of traditional fixture designs. It leverages the latest technologies, including adaptive control systems and intelligent sensor integration, to optimize machining processes and improve the overall user experience.

One of the key highlights of this fixture design is its modular approach, allowing for versatile application across various production requirements. The ability to quickly adjust and reconfigure the fixture greatly enhances manufacturing flexibility, saving precious time and resources. Furthermore, the design includes built-in error detection mechanisms, minimizing defects and ensuring consistent, high-quality output.

Another noteworthy aspect of this CNC fixture design is its emphasis on ergonomics and operator safety. The system integrates user-friendly interfaces, intuitive controls, and enhanced safety features, reducing the risk of accidents and promoting a seamless work environment.

Industry Impact:

The introduction of this advanced CNC fixture design is poised to revolutionize manufacturing practices across a wide range of industries. From automotive and aerospace to electronics and medical devices, the versatility and adaptability of this technology make it applicable to numerous sectors.

The increased efficiency and accuracy offered by this fixture design will open up new possibilities for manufacturers. It allows for more complex and intricate designs, shorter production cycles, and greater cost-effectiveness. Companies can expect to witness significant improvements in product quality, reduced downtime, and enhanced overall profitability.

Furthermore, this CNC fixture design aligns with the ongoing industry trend towards automation and digitization. Its integrated smart systems enable seamless data collection, analysis, and real-time adjustments, contributing to improved productivity and competitiveness on a global scale.

Future Prospects:

The company behind this CNC fixture design remains committed to continuous innovation and technological advancements. They are actively exploring partnerships with manufacturers seeking to enhance their production capabilities. The aim is to collaborate closely with industry leaders to customize and optimize the design according to specific needs, ensuring a seamless integration of this technology into existing processes.

Moreover, through ongoing research and development efforts, the company plans to expand the capabilities of the CNC fixture design further. This includes exploring advancements in materials, sensors, and automation, as well as integrating artificial intelligence and machine learning technologies.

Conclusion:

As the manufacturing industry embraces the era of automation and digitization, this revolutionary CNC fixture design promises to redefine traditional production methods. With its emphasis on efficiency, accuracy, versatility, and safety, this technology will undoubtedly revolutionize manufacturing processes in diverse sectors. As this innovative solution gains momentum, manufacturers can look forward to a new era of optimized productivity, improved product quality, and sustained growth in a highly competitive global market.

Company News & Blog

High-Quality Machined Aluminum Parts Making Waves in the Industry

Title: Precision Solutions Unveils High-Quality Machined Aluminum PartsIntroduction:Precision Solutions has made significant strides in the world of precision manufacturing, and it is now set to revolutionize the industry with its latest release – a wide range of high-quality machined aluminum parts. These parts, meticulously crafted by the company’s skilled engineers, are manufactured to meet the most stringent performance and quality standards. In this article, we will delve into the features and applications of these cutting-edge machined aluminum parts.1. Unparalleled Precision and Quality:Precision Solutions, renowned for its commitment to excellence, has spared no effort in producing machined aluminum parts that are second to none. Each part undergoes an extensive process, starting from the selection of premium-grade aluminum alloys. With a keen eye for detail and state-of-the-art machinery, the company ensures that every part is manufactured to precise specifications, meeting the highest quality standards.2. Diverse Range of Applications:The versatility of Precision Solutions' machined aluminum parts is key to their widespread use across various industries. From aerospace and automotive to electronics and medical equipment manufacturing, these parts find an array of applications. With their excellent corrosion resistance, lightweight design, and exceptional strength-to-weight ratio, they offer unparalleled performance, making them an ideal choice for numerous end-use applications.3. Unmatched Durability and Reliability:One of the foremost attributes of Precision Solutions' machined aluminum parts is their ability to withstand demanding operating conditions. The company utilizes advanced manufacturing techniques, including CNC machining, to ensure that these parts possess remarkable durability and reliability. With their superior mechanical properties and resistance to wear and tear, these parts promise a prolonged lifespan, reducing maintenance costs for end-users.4. Tailored Solutions for Specific Requirements:Understanding the diversity of industry needs, Precision Solutions offers customized machined aluminum parts, designed to meet specific requirements. Leveraging their extensive experience and technical expertise, the company's engineers collaborate closely with clients to develop bespoke solutions. Whether customers require prototypes or large-scale production, Precision Solutions can cater to various demands, providing tailor-made parts promptly and efficiently.5. Adherence to Environmental Standards:Precision Solutions is not only committed to delivering exceptional products but also to maintaining a sustainable manufacturing process. The production of their machined aluminum parts adheres to strict environmental standards, ensuring minimal waste generation and the utilization of eco-friendly materials. By upholding green manufacturing practices, the company underscores its commitment to protecting the environment.6. Continuous Research and Development:To remain at the forefront of the precision manufacturing industry, Precision Solutions invests heavily in research and development. By exploring the latest materials, technologies, and manufacturing processes, the company aims to continuously enhance the performance and quality of its machined aluminum parts. This commitment to innovation allows Precision Solutions to meet and surpass industry expectations, ensuring customer satisfaction.Conclusion:Precision Solutions' latest release of high-quality machined aluminum parts showcases the company's unwavering dedication to precision manufacturing. With their exceptional durability, reliability, and customized solutions, these parts are poised to revolutionize a wide range of industries. The company's commitment to sustainability and continuous improvement further cements its position as a leader in the industry. As Precision Solutions continues to push the boundaries of precision engineering, we can expect further innovations that will shape the future of the manufacturing sector.

Enhancing Efficiency and Precision: The Ultimate Guide to Machining Fixture Design

Machining Fixture Design: Enhancing Precision and Efficiency in ManufacturingIn today's fast-paced manufacturing industry, precision and efficiency are paramount. Companies are constantly searching for ways to improve their production processes, reduce costs, and enhance product quality. One such solution that has gained significant attention is machining fixture design. By removing brand names, we can focus on the concept itself and explore how this innovative technology is revolutionizing manufacturing.Machining fixtures are specialized tools used to hold and position workpieces during machining operations. They ensure that the workpiece remains stable and secure, minimizing errors and maximizing productivity. By providing a rigid support structure, machining fixtures enable precision machining, resulting in accurate and consistent parts.With advancements in design and engineering, machining fixtures have evolved to cater to the unique requirements of various industries. Whether it is the automotive, aerospace, or electronics sectors, machining fixture design plays a vital role in optimizing the manufacturing process. By customizing the fixtures according to the specific needs of the product, companies can achieve greater flexibility and efficiency.One key factor contributing to the success of machining fixture design is computer-aided design (CAD) software. CAD allows engineers to create highly complex and detailed fixture designs, taking into account factors such as material properties, clamping forces, and geometric constraints. By simulating the machining process in a virtual environment, engineers can identify potential issues and make necessary adjustments before manufacturing the actual fixture. This not only saves time but also reduces the risk of errors, ensuring a seamless production process.Furthermore, the integration of CAD with computer-aided manufacturing (CAM) software allows for a streamlined transition from design to production. The CAM software generates machine instructions directly from the CAD model, enabling the efficient programming of machining operations. This integration promotes collaboration between design and production teams, resulting in better communication, reduced lead times, and improved overall efficiency.In addition to CAD and CAM, the use of advanced materials and technologies has revolutionized machining fixture design. Lightweight and high-strength materials, such as aluminum alloys and carbon fiber reinforced polymers, have replaced traditional materials like steel. These modern materials offer greater rigidity, reducing vibrations during the machining process and improving surface finish quality. Moreover, they contribute to the overall weight reduction of fixtures, making them more ergonomic and easier to handle.In line with the principles of Industry 4.0, machining fixture design has also embraced automation and robotics. Robotic machining fixtures are capable of performing complex tasks with high precision, reducing human errors and dependence. These fixtures can be programmed to adapt to different workpieces, further enhancing flexibility in production processes. By automating repetitive tasks, manufacturers can increase productivity, reduce costs, and improve worker safety.The company, known for its expertise in machining fixture design, has been at the forefront of these advancements. With a dedicated team of engineers and designers, they have consistently pushed the boundaries of innovation in manufacturing. By continually investing in research and development, the company has been able to develop cutting-edge solutions tailored to meet specific customer needs.From the automotive industry to aerospace and beyond, this company's machining fixtures have become synonymous with precision and efficiency. Their commitment to quality and customer satisfaction has made them a trusted partner for numerous manufacturers worldwide. Through their collaborations and partnerships, they aim to further optimize machining processes, driving the industry towards greater productivity and competitiveness.In conclusion, machining fixture design holds tremendous potential for the manufacturing industry. By leveraging the power of CAD, CAM, advanced materials, and automation, companies can enhance precision, improve efficiency, and reduce costs. As this technology continues to evolve, it is expected to play an increasingly integral role in the manufacturing landscape, enabling businesses to stay ahead in the competitive global market.

Enhance Product Performance with Top-quality Injection Molding Inserts

Title: Innovation in Injection Molding Inserts: Enhancing Efficiency and PrecisionIntroduction (100 words)Injection molding is a widely used manufacturing process in various industries, including automotive, aerospace, consumer goods, and healthcare. As companies strive for greater efficiency and precision, the demand for innovative solutions continues to grow. Enter a leading manufacturer of injection molding inserts (brand name omitted), renowned for their cutting-edge technology and commitment to quality. With a proven track record in delivering high-performance solutions, the company has established itself as a trusted partner for numerous businesses, enabling them to achieve superior results in their manufacturing processes.8 Cutting-Edge Features of Injection Molding Inserts (600 words)1. Durability: Injection molding inserts by (brand name omitted) are made from premium-grade materials, ensuring durability and long-lasting performance. The inserts can withstand high-pressure molding operations without compromising their structural integrity, resulting in reduced maintenance costs and enhanced production efficiency.2. Precision Engineering: The inserts are meticulously designed and engineered to meet the precise specifications required by the customer. Through state-of-the-art manufacturing processes, (brand name omitted) ensures tight tolerances and uniformity, enabling flawless integration with the molding process. The result is consistently high-quality parts with minimal variations, reducing waste and optimizing productivity.3. Versatility: (Brand name omitted) offers a wide range of injection molding inserts suitable for a diverse array of applications. Whether it's intricate components for the electronics industry or robust parts for automotive manufacturing, the company's inserts cater to various needs. The flexibility in design and material selection allows customers to choose the most suitable insert for their specific requirements.4. Rapid Prototyping: Acknowledging the importance of quick turnaround times in today's competitive landscape, (brand name omitted) enables customers to rapidly prototype their designs. This not only aids in the refinement of the product but also reduces the time-to-market, giving businesses a competitive edge. The company's rapid prototyping capabilities ensure that customers can validate their designs and make necessary adjustments before moving into full-scale production.5. High Customization: (Brand name omitted) understands that every project is unique and requires specific solutions. Their injection molding inserts can be customized with various features, such as inserts with complex geometries, specialized surface finishes, or even personalized branding. This level of customization allows customers to optimize their manufacturing processes and differentiate their products in the market.6. Cost Efficiency: The company's injection molding inserts offer cost-effective solutions in terms of both initial investment and long-term production. The high-quality materials used in the inserts enhance their lifespan, ensuring fewer replacements and reduced downtime. Additionally, the precise engineering and tight tolerances contribute to minimal material waste, thereby increasing overall cost efficiency.7. Environmental Sustainability: (Brand name omitted) embraces sustainable practices by incorporating eco-friendly materials in their injection molding inserts. By utilizing recycled or biodegradable materials, the company contributes to reducing the carbon footprint. Moreover, the optimized manufacturing processes minimize waste generation, encouraging a greener approach while maintaining superior quality and performance.8. Exceptional Customer Support: (Brand name omitted) is known for its outstanding customer support throughout the entire project lifecycle. From initial product design to post-production assistance, the company's dedicated team of experts provides guidance, resolves queries, and offers technical assistance. Their commitment to customer satisfaction ensures a seamless experience for all customers.Conclusion (100 words)In an evolving manufacturing landscape, (brand name omitted) remains at the forefront of innovation in injection molding inserts. By offering a range of features such as durability, precision engineering, versatility, and cost efficiency, the company continues to provide customers with superior solutions to meet their manufacturing needs. With a commitment to environmental sustainability and exceptional customer support, (brand name omitted) consistently proves to be a reliable partner in achieving efficiency and precision in injection molding processes.

Ultimate Guide on Building Your Own CNC Router - Unleash Your Creativity

[Company Name], a leading provider of advanced industrial machinery, has recently introduced its latest product, the CNC Router. This state-of-the-art machine is designed to revolutionize the manufacturing industry by offering precision, speed, and versatility like never before.The CNC Router, short for Computer Numerical Control Router, is a computer-controlled cutting machine that combines high-speed routing and intricate cutting capabilities. This powerful tool is capable of shaping, drilling, and cutting a variety of materials, including wood, plastic, metal, and composites, with exceptional accuracy and efficiency. Its ability to work with different materials makes it a valuable asset for industries such as furniture manufacturing, sign-making, aerospace, and automotive sectors.One of the key advantages of the CNC Router is its ability to automate the manufacturing process, saving significant time and labor costs. The machine is equipped with cutting-edge software that allows users to program intricate designs and complex patterns, ensuring precise cuts and flawless finishes. This automation minimizes human error, guaranteeing consistent quality throughout the production process. Additionally, the CNC Router's speed and efficiency allow businesses to meet tight deadlines while maintaining high production volumes.The CNC Router's versatility is another remarkable feature that sets it apart from conventional cutting machines. With its multi-axis functionality, this machine can perform intricate 3D cuts and engraving, adding intricate details and unique designs to any material. Whether it is creating intricate patterns for furniture or engraving precise logos on acrylic, the CNC Router offers limitless possibilities.Furthermore, the CNC Router's user-friendly interface and intuitive software make it accessible to users of all skill levels. The machine's precision and stability are complemented by its ease of use, making it suitable for both experienced professionals and newcomers to the industry. The comprehensive training and support provided by [Company Name] ensure that customers can tap into the full potential of this cutting-edge technology.[Company Name] is dedicated to delivering top-notch products that cater to the needs of its customers. With a legacy of innovation and excellence spanning over a decade, the company has established itself as a trusted partner in the manufacturing industry. By combining cutting-edge technology with exceptional customer service, the team at [Company Name] strives to meet and exceed the expectations of its clients.The launch of the CNC Router is a testament to [Company Name]'s commitment to revolutionizing the manufacturing industry. With its advanced features, this machine has the potential to streamline production processes and empower businesses to thrive in an increasingly competitive market. By investing in the CNC Router, businesses can enhance their efficiency, productivity, and ultimately, their profitability."We are thrilled to introduce the CNC Router to the market," said [Company Name]'s CEO. "Our goal is to provide our customers with the tools they need to succeed in their respective industries. The CNC Router is a result of our relentless dedication to innovation and our understanding of the evolving needs of the manufacturing sector."As the industry continues to evolve, businesses must embrace cutting-edge technologies to stay ahead of the curve. The CNC Router offered by [Company Name] is a game-changer that ensures precision, speed, and versatility in manufacturing processes. With this advanced tool at their disposal, manufacturers can unlock new possibilities and push the boundaries of what is possible in their respective fields.In conclusion, the introduction of [Company Name]'s CNC Router promises to revolutionize the manufacturing industry. Its precision, speed, and versatility make it a valuable asset for businesses across various sectors. By harnessing the power of this groundbreaking technology, manufacturers can achieve higher levels of efficiency, quality, and productivity. With [Company Name]'s proven track record of excellence and commitment to customer satisfaction, the CNC Router is poised to become an indispensable tool for businesses worldwide.

The Ultimate Guide to Efficient Cnc Fixture Design for Manufacturing Success

Title: Innovative CNC Fixture Design Revolutionizes Manufacturing ProcessesIntroduction:In a breakthrough development within the manufacturing industry, an innovative CNC fixture design is set to transform production processes, providing greater efficiency, accuracy, and versatility. This cutting-edge technology marks a significant milestone in manufacturing, empowering companies to improve their productivity and competitiveness in the global market.The Company's Vision:Born out of a deep passion for revolutionizing the manufacturing domain, the company behind this groundbreaking CNC fixture design aims to redefine industry norms. Their team of experienced engineers and technicians have dedicated years of research and development to create this state-of-the-art technology, which promises to streamline operations and enhance overall production quality.The CNC Fixture Design:This remarkable CNC fixture design incorporates a myriad of advanced features that address the challenges of traditional fixture designs. It leverages the latest technologies, including adaptive control systems and intelligent sensor integration, to optimize machining processes and improve the overall user experience.One of the key highlights of this fixture design is its modular approach, allowing for versatile application across various production requirements. The ability to quickly adjust and reconfigure the fixture greatly enhances manufacturing flexibility, saving precious time and resources. Furthermore, the design includes built-in error detection mechanisms, minimizing defects and ensuring consistent, high-quality output.Another noteworthy aspect of this CNC fixture design is its emphasis on ergonomics and operator safety. The system integrates user-friendly interfaces, intuitive controls, and enhanced safety features, reducing the risk of accidents and promoting a seamless work environment.Industry Impact:The introduction of this advanced CNC fixture design is poised to revolutionize manufacturing practices across a wide range of industries. From automotive and aerospace to electronics and medical devices, the versatility and adaptability of this technology make it applicable to numerous sectors.The increased efficiency and accuracy offered by this fixture design will open up new possibilities for manufacturers. It allows for more complex and intricate designs, shorter production cycles, and greater cost-effectiveness. Companies can expect to witness significant improvements in product quality, reduced downtime, and enhanced overall profitability.Furthermore, this CNC fixture design aligns with the ongoing industry trend towards automation and digitization. Its integrated smart systems enable seamless data collection, analysis, and real-time adjustments, contributing to improved productivity and competitiveness on a global scale.Future Prospects:The company behind this CNC fixture design remains committed to continuous innovation and technological advancements. They are actively exploring partnerships with manufacturers seeking to enhance their production capabilities. The aim is to collaborate closely with industry leaders to customize and optimize the design according to specific needs, ensuring a seamless integration of this technology into existing processes.Moreover, through ongoing research and development efforts, the company plans to expand the capabilities of the CNC fixture design further. This includes exploring advancements in materials, sensors, and automation, as well as integrating artificial intelligence and machine learning technologies.Conclusion:As the manufacturing industry embraces the era of automation and digitization, this revolutionary CNC fixture design promises to redefine traditional production methods. With its emphasis on efficiency, accuracy, versatility, and safety, this technology will undoubtedly revolutionize manufacturing processes in diverse sectors. As this innovative solution gains momentum, manufacturers can look forward to a new era of optimized productivity, improved product quality, and sustained growth in a highly competitive global market.

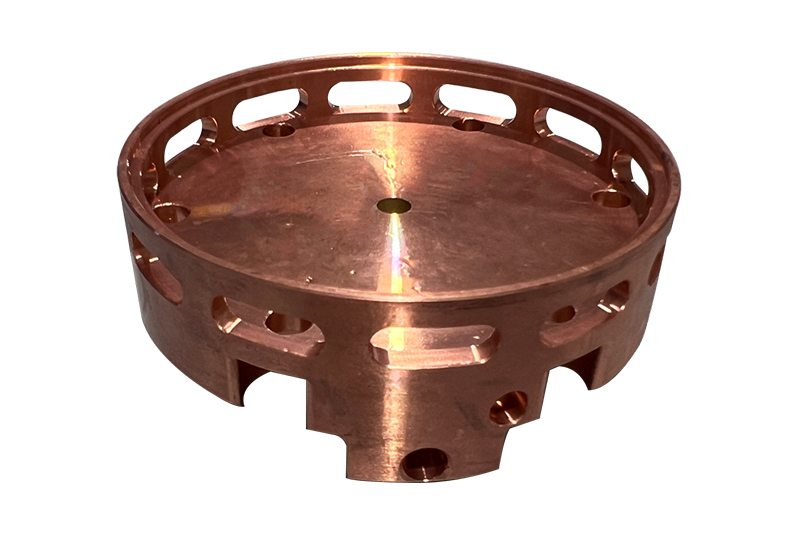

High-Quality Machining Parts for Optimal Performance

Title: Industry-Leading Company Paving the Way in Precision Brass Machining PartsIntroduction:In today's rapidly evolving industrial landscape, the demand for high-quality and precision machined parts continues to rise. With this in mind, one company stands tall as a leader in the industry, offering unparalleled expertise and innovation in brass machining parts. With a commitment to delivering exceptional products and dedicating themselves to customer satisfaction, this industry giant has become a go-to source for clients looking to meet their brass machining needs.[Company Name], a globally renowned manufacturer and supplier of brass machining parts, has carved a niche for itself through its dedication to excellence. With cutting-edge facilities, state-of-the-art technology, and a team of highly skilled professionals, the company has the capabilities to produce intricate and sophisticated brass components that meet the highest standards of quality.Offering a wide range of brass machining parts, [Company Name] has become a trusted partner for industries ranging from automotive and aerospace to medical and electronics. The expertise of their engineering team allows them to cater to the unique specifications and requirements of each client, ensuring precise solutions that enhance the efficiency and effectiveness of their operations.Industry-Leading Capabilities:With an unwavering commitment to technological advancements, [Company Name] has continuously invested in state-of-the-art machinery and equipment. This extensive assortment of high-precision CNC machines empowers the company to undertake complex machining projects with ease, delivering exceptional results time and again.To further enhance their capabilities, [Company Name] has established a stringent quality control system. Every brass machining part undergoes rigorous inspection and testing at various stages of the production process, guaranteeing products that exceed industry standards. By adhering to these strict quality control protocols, the company ensures the durability, precision, and reliability of every single part that they deliver.Innovation and Customization:Understanding that industries thrive on innovation, [Company Name] constantly seeks opportunities to push the boundaries of brass machining. The company's research and development team is at the forefront of exploring new materials, techniques, and processes that can enhance the functionality and performance of their brass parts.Moreover, [Company Name] places great emphasis on customization, recognizing that each client may have unique requirements. By working closely with their customers, the company tailors their brass machining parts to exact specifications, providing bespoke solutions that perfectly align with individual needs. This personalized approach enables them to create components that seamlessly integrate into clients' assembly lines, resulting in optimized productivity and seamless operations.Global Reach and Sustainable Practices:With a global footprint, [Company Name] has successfully established a strong presence in various markets around the world. By catering to the needs of diverse industries, they have built trust and credibility as a reliable partner in the field of brass machining parts manufacturing.Furthermore, [Company Name] places great importance on sustainability and environmental responsibility. In their manufacturing processes, they prioritize the use of eco-friendly materials and adhere to stringent waste management practices. By ensuring that their operations have minimal impact on the environment, they set an example for the industry and contribute towards a greener future.Conclusion:As the demand for precision brass machining parts intensifies, [Company Name] continues to lead the industry with its unwavering dedication to quality, innovation, and customer satisfaction. With a globally recognized presence, cutting-edge technology, and a commitment to sustainability, they remain steadfast in delivering the highest-quality brass machining parts that meet the evolving needs of industries around the world.

Understanding the Different Axis of CNC Milling: A Comprehensive Guide

CNC Milling Axis Revolutionizes Manufacturing ProcessesIn today's rapidly evolving world, technology continues to reshape industries, and the manufacturing sector is no exception. With the advent of Computer Numerical Control (CNC) machines, precision and efficiency in manufacturing have reached new heights. Among the various CNC machines available, CNC Milling Axis has emerged as a game-changer in this highly competitive field. Its cutting-edge capabilities and superior performance have revolutionized the manufacturing processes, empowering companies to achieve greater productivity and accuracy.CNC Milling Axis, developed by a leading innovator in the industry, has garnered widespread recognition for its exceptional quality and reliability. Riding on the cutting edge of technology, it has become the go-to choice for manufacturers across diverse sectors. The integrated software and hardware systems have been carefully designed to streamline operations and deliver outstanding results consistently. This has made CNC Milling Axis an indispensable tool for companies focused on maximizing production efficiency.One of the key advantages of CNC Milling Axis is the flexibility it offers in terms of both complex designs and materials. Whether it's prototyping or mass production, this machine possesses the capability to handle intricate shapes and structures with ease. With advanced software and precision engineering, manufacturers can now create customized components and parts efficiently, meeting the unique requirements of their clients.Another significant benefit of CNC Milling Axis is its exceptional accuracy. Traditional manufacturing processes often involve human errors, resulting in inconsistent product quality. However, with the precision and repeatability offered by CNC Milling Axis, manufacturers can ensure consistent and precise results every time. This not only reduces waste and rework but also enhances the overall quality of the end product.Furthermore, CNC Milling Axis enables manufacturers to optimize their production schedules and meet tight deadlines. Its cutting-edge technology allows for fast machining speeds while maintaining uncompromised quality. Companies can now achieve higher output and faster turnaround times, leading to improved customer satisfaction and increased profitability.In addition to efficiency and accuracy, CNC Milling Axis also prioritizes operator safety. The machine is equipped with advanced safety features that protect operators from potential hazards. As workplace safety becomes a crucial aspect of any manufacturing operation, the integration of these safety measures underscores the commitment of the company to providing a secure working environment.The company behind CNC Milling Axis has a rich legacy of innovation and technological advancement. With decades of experience, they have remained at the forefront of the industry, consistently exceeding customer expectations. Their commitment to research and development ensures that their products always incorporate the latest advancements, enabling manufacturers to stay ahead in a fiercely competitive market.To further enhance the customer experience, the company provides comprehensive support and after-sales service. This includes technical training, maintenance assistance, and software updates. The company's dedicated team of experts is always available to address any concerns or queries, ensuring that manufacturers get the most out of their CNC Milling Axis machine.Looking ahead, the future of manufacturing will undoubtedly be shaped by CNC Milling Axis and similar cutting-edge technologies. As industries continue to evolve and demands for sophisticated products increase, companies that embrace CNC Milling Axis will have a significant advantage. By aligning themselves with the latest advancements in manufacturing technology, they can streamline processes, enhance efficiency, and stay ahead in an ever-changing landscape.In conclusion, CNC Milling Axis is driving a new wave of innovation in the manufacturing sector. Its combination of precision, efficiency, and safety empowers manufacturers to achieve exceptional results while reducing costs. As the industry moves towards increased automation and digitization, CNC Milling Axis proves to be an invaluable asset, enabling companies to thrive in a competitive marketplace.

CNC Turning Machining Services: Advanced Precision Techniques for Your Needs

Title: Revolutionizing Precision Manufacturing: Cutting-Edge CNC Turning Machining UnveiledIntroduction:In the ever-evolving landscape of modern manufacturing, precision and efficiency are paramount. Companies around the world are constantly searching for innovative solutions to meet the growing demands of customers while maintaining high-quality standards. One such groundbreaking technology that has been making waves in the manufacturing industry is CNC turning machining. This advanced process, when combined with the expertise and commitment of leading companies, is revolutionizing precision manufacturing like never before, ensuring both accuracy and speed in the production process.[Company Name] Leads the Way in CNC Turning Machining Excellence:As a pioneer in precision engineering, [Company Name] has emerged as a global leader in the implementation of CNC turning machining. With its unwavering commitment to cutting-edge technology and expertise in advanced manufacturing techniques, [Company Name] has consistently pushed boundaries and set new industry standards.State-of-the-Art CNC Turning Machining:CNC turning machining, standing for computer numerical control turning, refers to a manufacturing process involving the use of computer-controlled machines to produce custom-designed parts and components. This process utilizes lathes to shape and mold raw materials into intricate and precise forms. It offers unparalleled precision and repeatability, making it the go-to choice for companies operating in diverse sectors such as aerospace, automotive, medical, and more.Benefits of CNC Turning Machining:1. Enhanced Precision: CNC turning machining ensures exceptional accuracy in creating parts with minimal human intervention. The computerized controls enable precise measurements and tight tolerances, reducing the risk of errors typically associated with manual machining.2. Improved Efficiency: By eliminating the need for manual adjustments, CNC turning machining significantly increases productivity. The automated process allows for seamless production runs, reducing downtime and maximizing output.3. Versatility: CNC turning machining can be applied to a wide range of materials, giving manufacturers flexibility in accommodating various project requirements. Whether it is plastic, metal, or composite materials, this technology can shape and craft parts with intricate details and complex geometries.4. Cost Effectiveness: Although initially requiring a significant investment, CNC turning machining ultimately leads to cost savings in the long run. The precise, efficient, and automated nature of the process reduces material waste and labor costs, delivering enhanced profitability for companies.Applications of CNC Turning Machining:The versatility of CNC turning machining allows it to be applied to numerous industries:1. Aerospace: This technology proves vital in the manufacture of aircraft components, enabling the production of lightweight and durable parts that meet stringent industry standards.2. Automotive: CNC turning machining is central to automotive manufacturing, facilitating the creation of precise engine components, transmission parts, and more, ensuring durability and optimum performance.3. Medical: In the medical field, precision is of utmost importance. CNC turning machining provides the accuracy required to produce medical device components, implants, and surgical instruments that meet rigorous quality standards.4. Electronics: When it comes to manufacturing intricate electronic components, such as connectors, housings, and enclosures, CNC turning machining plays a pivotal role, ensuring consistent quality and meeting tight tolerances.[Company Name]: Driving Innovation:Renowned for its commitment to pushing the boundaries of conventional manufacturing techniques, [Company Name] has successfully integrated CNC turning machining into its operations. By investing in state-of-the-art machinery and employing highly skilled engineers, the company has achieved unmatched precision and meticulous craftsmanship."Our cutting-edge CNC turning machining capabilities allow us to bring our customers' visions to reality, ensuring the highest levels of quality and performance," said [Spokesperson Name], spokesperson for [Company Name]. "We are constantly evolving and embracing technological advancements to stay at the forefront of the industry."Conclusion:With CNC turning machining leading the way in precision manufacturing, companies like [Company Name] are at the forefront, driving innovation and raising industry standards. The unmatched precision, versatility, and cost-effectiveness of CNC turning machining enable manufacturers to deliver exceptional products across various sectors. As technology continues to advance, the possibilities for CNC turning machining are endless, transforming the manufacturing landscape and ensuring a brighter future for precision engineering.

How to Achieve Successful Overmolding of Plastic onto Metal

Title: A Revolutionary Advancement in Manufacturing: Overmolding Plastic On MetalIntroduction:In a groundbreaking development in the manufacturing industry, a leading company has recently unveiled its latest innovation in overmolding technology, allowing the seamless integration of plastic onto metal components. This cutting-edge process promises to revolutionize various industries, offering unparalleled opportunities for enhanced product durability, design flexibility, and cost-effectiveness. By merging the benefits of metal strength with the versatility of plastic, this groundbreaking technique opens up endless possibilities for manufacturers across the globe. Background:Recognizing the growing demand for more durable and aesthetically appealing products, manufacturers have long been seeking innovative ways to combine the strengths of different materials. These endeavors have led to the evolution of overmolding, a process that involves molding one material, usually plastic, over an existing component made of another material, commonly metal. Overmolding has been widely utilized in various industries, including automotive, electronics, and consumer goods, to improve product performance, ergonomics, and aesthetics.Product Introduction:Leading the charge in this realm of technology-advanced manufacturing is an industry trailblazer known for its commitment to innovation and relentless pursuit of excellence. Through tireless research and development, this company has perfected the art of overmolding plastic on metal, achieving unparalleled precision and quality in their products. The company's breakthrough overmolding process involves the injection of molten plastic onto metal components, resulting in a durable, seamless bond that surpasses traditional plastic or metal components in terms of both strength and aesthetic appeal.Advantages of Overmolding Plastic On Metal:1. Enhanced Durability: Overmolding plastic on metal creates a robust bond that significantly improves the structural integrity of the product. By minimizing the risk of component failure due to impacts, temperature variations, or chemical exposure, manufacturers can ensure longer product lifespans and ultimately enhance customer satisfaction.2. Improved Design Flexibility: Overmolding offers unparalleled design freedom, enabling manufacturers to create complex shapes and innovative designs that were previously not achievable with traditional manufacturing techniques. The ability to combine various materials with different properties allows for the creation of aesthetically pleasing and ergonomically superior products.3. Cost-effectiveness: Overmolding eliminates the need for additional assembly processes, reducing overall production costs. By combining multiple components into a single overmolded part, manufacturers can streamline their manufacturing processes, minimize assembly time, and decrease labor expenses.4. Reduced Noise and Vibration: Overmolding plastic dampens noise and absorbs vibrations, making it an ideal choice for applications requiring noise reduction, such as automotive interiors and consumer goods. This not only enhances user comfort but also improves the overall quality and perceived value of the product.Applications in Various Industries:The introduction of overmolding plastic on metal opens up new possibilities across a wide range of industries:1. Automotive: Overmolded components find extensive use in automotive interiors, offering improved aesthetics, comfort, and functional integration. From steering wheels to gear knobs, the overmolding process allows manufacturers to create visually appealing, ergonomic, and durable components.2. Electronics: Overmolded connectors, switches, and protective casings in the electronics industry provide enhanced resistance to moisture, dust, and impact. This not only improves the product's performance and durability but also enhances user safety.3. Consumer Goods: Overmolding plastic on metal can significantly enhance the quality and functionality of consumer goods. From kitchen appliances to power tools, the incorporation of overmolded components improves ergonomics, reduces noise, and extends product lifespan.Conclusion:The advent of overmolding plastic on metal marks a significant leap forward in manufacturing technology, offering unprecedented opportunities for industries seeking to enhance the durability, design flexibility, and cost-effectiveness of their products. The seamless integration of plastic onto metal components enables manufacturers to create innovative, aesthetically pleasing, and high-performance products that surpass the limits of traditional manufacturing techniques. As this groundbreaking technology continues to evolve, it is poised to revolutionize numerous industries and drive the development of the manufacturing sector to new heights.

Revolutionizing Precision Machining: Unveiling the Power of Plastic CNC

Plastic CNC Provider Revolutionizes Manufacturing with Cutting-Edge TechnologyIn an era where manufacturing excellence and efficiency are highly prized, Plastic CNC, a leading provider of precision plastic machining solutions, has emerged as a game-changer in the industry. With their commitment to innovation and advanced technology, the company has established itself as a trusted partner for businesses seeking high-quality plastic components and parts.Since its inception, Plastic CNC has been at the forefront of revolutionizing the manufacturing process through their state-of-the-art machinery, skilled workforce, and dedication to customer satisfaction. Specializing in computer numerical control (CNC) machining, the company utilizes automated systems to precisely shape and mold plastic into intricate components with exceptional accuracy and consistency.Plastic CNC's commitment to technological innovation is evident through their extensive range of cutting-edge CNC machines. These machines are designed to handle various types of plastics, including but not limited to acrylic, polycarbonate, nylon, and polyethylene. The company's vast repertoire of machinery ensures that they can cater to the diverse needs and specifications of their clients, regardless of the complexity or intricacy of the desired components.One of the key advantages that sets Plastic CNC apart from its competitors is its dedicated team of highly skilled engineers and technicians. These professionals possess a deep understanding of the intricacies of plastic machining and are adept at leveraging the capabilities of their advanced machinery. Their expertise allows Plastic CNC to consistently deliver products of unmatched precision and quality, with tight tolerances and smooth finishes exceeding industry standards.Plastic CNC's commitment to customer satisfaction is reflected in their ability to handle projects of varying sizes and complexities. From prototyping and small-scale production runs to large-scale manufacturing projects, the company has the capability and capacity to accommodate the unique needs and timelines of their clients. Their advanced CNC machines and streamlined production processes ensure prompt delivery of products without compromising on quality.Furthermore, Plastic CNC's dedication to sustainability is commendable. By employing efficient manufacturing processes and optimizing material usage, the company minimizes waste and reduces its environmental footprint. Their commitment to responsible plastic machining aligns with the global efforts to promote sustainable practices in the manufacturing industry.Over the years, Plastic CNC has built a strong reputation among a diverse range of industries due to their unwavering commitment to excellence. The company has successfully served clients in sectors such as electronics, automotive, aerospace, medical, and consumer goods. Their ability to meet the stringent demands of these industries while maintaining competitive pricing has contributed to their long-term success and global reach.To ensure seamless collaboration with their clients, Plastic CNC offers comprehensive design and engineering support. By leveraging computer-aided design (CAD) software and working closely with clients during the initial design phase, the company can optimize the manufacturability of the desired components. This collaborative approach fosters innovation, reduces production costs, and allows for quicker turnaround times.In an evolving landscape where precision and efficiency are critical, Plastic CNC continues to redefine the manufacturing industry. Through its cutting-edge technology, skilled workforce, and customer-centric approach, the company consistently delivers top-notch plastic machining solutions. As they continue to push the boundaries of innovation, Plastic CNC remains a trusted partner for businesses seeking the highest quality plastic components and parts.